Are you currently working on a construction project in Leichhardt or planning to start one? Whether it’s your own home, a new office, or a retail renovation, any project will be incomplete without proper utilities. For this, the most efficient way to create holes in your structure is by core drilling and using Diamond Core Drill Bits. Let us review some basic questions about core drilling.

What is a core drill?

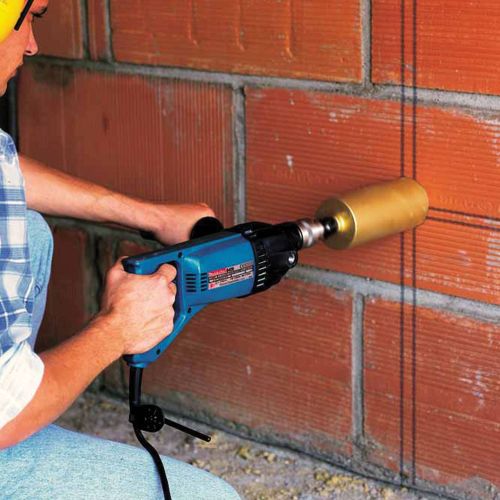

A core drill is a drill used to cut a perfectly round hole in any surface and material. This cylindrical drill equipment can be electric, hydraulic or pneumatic. The difference of core drills to other types is that its bit is hollow, allowing the drilled material to get extracted. It has different types, from the more powerful types used in large-scale construction, to hand-held home use types. It effectively cut out precise holes in various materials such as concrete, stone, aggregates, rock, minerals, marble, granite, brick, porcelain, and ceramic. Core drills used specifically for metal are called annular cutters.

Who needs core drill?

Engineers, contractors, and homebuilders with construction projects or renovations use core drills in residential projects when drilling for dryer vents, drain holes, fireplaces and smaller electrical and plumbing works.

Why is core drilling essential in concrete construction?

The extracted material from the drill is called the core. This sample will be tested for properties such as permeability and strength. Engineers need to determine the concrete’s strength for their project to be well-built.

WHEN is core drilling used in other industries?

There is a wide range of applications in different industries. In building construction, core drilling creates passageways for building utilities such as heating, ventilation and air conditioning systems (HVAC), plumbing and sanitary systems, electrical systems, and electronic and cable systems. Core sampling for roads and strength tests for various materials are also some applications. In mineral explorations, coring is done several feet into the ground used by geologists.

Where do I get supplies and tools?

First of all, study your work scope to know what power and speed of core drill you will be needing. You will need Core Drill Bits for all core drills, which come in different lengths and diameters. There are wet core drill bits and dry core drill bits available, but water is usually needed for concrete core drilling. Diamond-topped core drills are the most effective against the toughest materials like concrete. These diamond core drills fade in constant usage and depending on the application, bits usually last around 100 – 120 holes. Factors like speed, pressure and material density affect lifespan.

How long does concrete core drilling take?

The cutting of the material itself is very quick, but there are preparations to do before proceeding to core drilling. Scan the area to be drilled to ensure that nothing underneath may be present, such as existing wires or pipes, that are potentially hazardous. Each equipment may come with specific instructions, so it’s better to review them. It’s about selecting the right core barrel for the material, having enough water, and steady positioning.

The hardness of the stone used in concrete, the actual core drill equipment, and the person doing the job, affect the time to finish drilling. For basic applications, it is a minute or less for a 4″ concrete slab. More than just the speed, remember it is the quality of the drill that matters the most.