Steel has various kinds. They are differentiated on the basis of grades, specifications, finish and shapes. The types make steel useful for different purposes like in infrastructure, various appliances, vehicles, wind turbines, etc. What kind of steel it will be depends on the manufacturing process. So, there can be many types, hot rolled steel, cold rolled steel and also HR sheet.

Difference between hot rolled and cold rolled steel

The main difference lies in how these are processed. Hot rolled steel is processed with heat while cold-rolling is done at room temperature. It is important to understand the differences between these two so that you can choose one over another based on your needs.

Hot Rolled Steel

The temperature needs to be more than 1,700°F for manufacturing hot rolled steel. This temperature is used for recrystallization of most steels. It is processed in such a way to make it easier to work with.

The process starts with heating a large, rectangular metal called the billet and sending it for preprocessing. The metal is then flattened to form a large roll. Then it is kept in a very high temperature and processed through a series of rollers until the manufacturer is happy with the finished product. When it is cooled down, steel shrinks a little.As hot rolled steel needs to be cooled down after processing, there is not much you can do to change shape of the final product. Thus it cannot be used in places where precision is needed, it can only be used where precision doesn’t matter. It is often used in railway tracks and in construction projects.

Here are a few characteristics of Hot Rolled Steel:

- The surface is not smooth but scaled, which happens as the steel is cooled down from extremely high temperature.

- The edges are rounded to be used for bar and plate products.

- The heating and cooling results in slight distortions and gives rise to a trapezoidal form instead of squared angles.

Benefits of hot rolled steel

As hot rolled steel requires less processing than cold rolled steel, the manufacturing cost is quite cheap. It is made to cool down in room temperature so there are no internal stresses required which are a result of quenching or work-hardening processes. Hot rolled steel is perfect for uses where material strength is needed and not smooth finishes.

Cold Rolled Steel

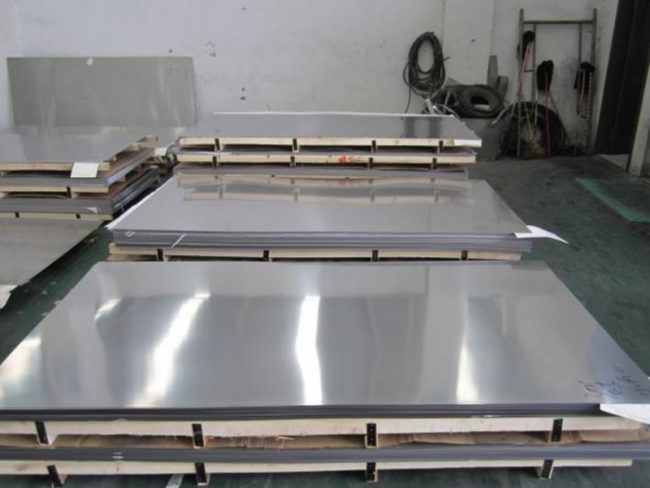

Cold rolled Steel is actually hot rolled steel which is processed a couple of more times. After the hot rolled steel has cooled down, it is re-rolled again at room temperature to get more accurate dimensions and smoother surface.

Some features of Cold Rolled Steel:

- It is far better than other kind of steels, with finished surface.

- The surface is usually quite smooth and feels oily to touch.

- The boys are in good shape with well-defined edges and corners.

- The tubes are uniform and straight.

Benefits of Cold Rolled Steel

As it has better surface quality than hot rolled steel, it is used specifically for applications which need precise technicality. As there is no many additional processing of the steel, these comes at a higher price. Now coming to physical characteristics, the Cold Rolled Steels are harder in texture and much stronger. The metal is shaped once it cools down or at a very low temperature. As a result of which, the hardness of the steel, the resistance power against tension breaking, and also the power of resistance against deformation are increased. But one disadvantage can be that it gives rise to internal stress within the material which leads to unpredictable warping if you forget to relieve it from stress before cutting it or grinding or welding.

Cold Forming Process

Cold forming process includes a metal sheet being placed in between rollers which compresses and squeezes it. The amount of pressure put in to compress it determines the how hard the finished product would be. There are a lot of cold rolling mills which manufactures different types of rolled products which can be as low in thickness as 0.05mm.

Cold formed steel can be of various types depending on to what extent the cold work was performed on it. They can be skin-rolled, quarter hard, half hard and full hard. This hardness due to cold working is called ‘temper’, which is very different from heat treatment temper.

While manufacturing the skin rolled steel in steel trading company, the thickness of the metal reduces to 0.5 to 1% which results in a smooth surface. The excessive wrinkling and stretching in the process is discarded. This increases the ductility of the metal.

Generally, the quarter hard, half hard and full hard has the reduction rate of 50%, which betters the yield point, but the metal becomes less ductile. The advantage of these products is that they can be used in places where too much bending of the metal is required without fracturing.