One of the most common ways to transport large or multiple kinds of cargo anywhere in the world is by shipping container. The average shipping containers are used to house a number of items while transporting the entire structure from place to place. In most cases, different types of shipping containers are utilized for transporting different items, allowing businesses to chose different shipping containers to suit their cargo transport needs. The evolution of the shipping container has now led to a better performing container during transport, as well as larger carrying capacities. For this reason, businesses have a number of options to consider if they are interested in buying or renting shipping containers. There is a wealth of information to know about shipping containers before they choose to buy or rent.

Shipping Containers: What to Know

Size is an important consideration to keep in mind if considering shipping containers for business transport purposes. Today, shipping containers come in many sizes to serve a number of needs for a diverse selection of businesses. The most common shipping container sizes include the 10-foot shipping container, the 30-foot shipping container, and the 40-foot shipping container. Shipping containers are also made from highly reinforced materials, notably steel and electrical components for storage containers with refrigeration or insulation systems.

Most storage containers are made from a variety of different materials such as the previously mentioned steel and aluminum. Newer storage containers use a special kind of material known as fiber reinforced polymer, usually combining the newer material with the traditional aluminum and steel.

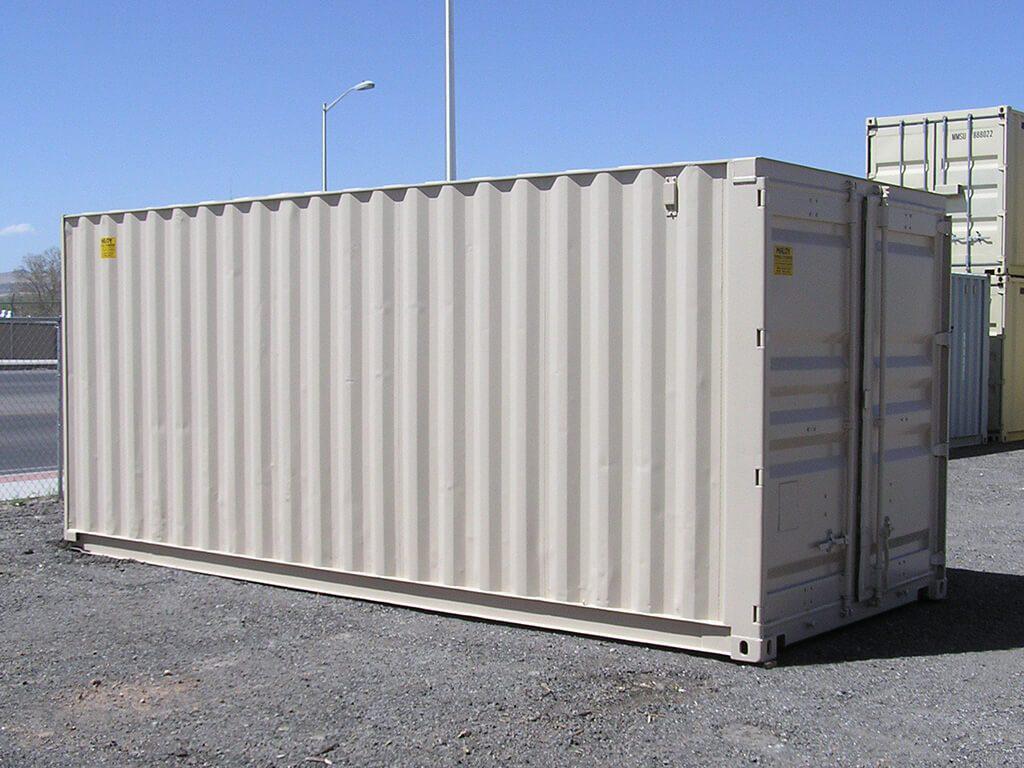

A storage container generally has a straightforward appearance. They are best known for their corrugated or ripple like walls, which are welded to end frames and rails to hold the structure together. Most storage containers have a closed top roof with doors that have hinges.

The steel container production process is straightforward, yet interesting. An average storage shipping container starts as several large sheets of steel, which are later prepared and cleaned before being corrugated to reinforce its overall strength.

The other components like the floor braces and the panels for the roof and walls get produced separately. Every component is then welded together as long with additional square tubing that is added to the top part of the walls. Floor panels are then put together to form a frame for the floor, in addition to the door and corner post of the storage container. Following the construction of these parts, each component is welded to the previously assembled structure, forming the basic form of the storage container. After the assembly, the storage container gets primed and completely painted. Additional post assembly takes, including installing wooden flooring and door hardware is also completed. The outer, inner, and flooring of the shipping storage containers are also weatherized for protection against the elements.

The straightforward construction of shipping containers leads to a number of containers that can be utilized in many business applications. For this reason, shipping containers are produced in various places around the world to fulfill transportation needs everywhere.